Stress-Strain curve

Stress-Strain curve

- Region OA in the graph is linear. Hook's law is obeyed. Solid behaves like elastic body. Point A is the elastic limit.

- In region AB, stress & strain are not proportional. But body can regain its original shape & size when the load is removed.

- Point B is called yield point & corresponding stress is called yield strength.

- When load is removed at point C between region B&D, body does not regain original dimension.

- Even stress is zero, strain is not zero in the region BD. Point C is called set point.

- At point C the material is in a permanent set & the deformation is called Plastic deformation.

- Point D is called ultimate stress. At this point wire becomes thin.

- Point E represents break point. Where the body physically breaks.

- If point D & E are very close, material is said to be brittle.

- If point D & E are far apart, material is said to be ductile.

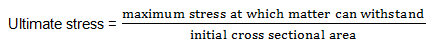

Ultimate stress - It is defined as the maximum stress that

can applied be to a material; so that it remain withstand.

Breaking stress - It is defined as the maximum stress at which

wire under stress physically breaks.

Working stress - It is the stress which is considered as the

allowable stress for design purpose.

working stress should always be smaller than Ultimate stress.

Factor of safety - It is the ratio of ultimate stress to working stress.

Comments

Post a Comment